Services

Design, Drawing, Assembly and Sale of Various Machinery and Equipment

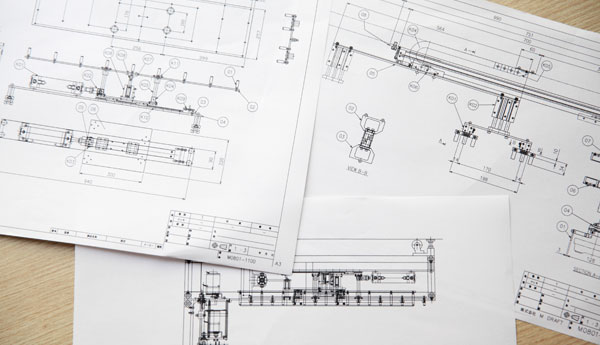

We design machines, primarily machinery and equipment for semiconductor production lines.

We also design storage equipment, and specialize in the design of many other machines, including automated carriers for nuclear power plants, automated carriers for refrigeration facilities, and liquid crystal manufacturing machines.

3D Printing Service

The 3D printer "Form 2” has a highly advanced function comparable to industrial-strength ones, and enables the output of various different shapes of objects. It responds to a wide range of needs such as product shape measurement and production of resin models, with high-definition finish.

Planning and Developmen of Teaching Equipment for Learning Japanese Monozukuri

We plan, design, sell, and run seminars on educational ICT-based basic-motion machine kits as teaching materials for children from kindergarten, elementary school to junior high school.

We aim to resolve the shortage of technicians for a greater future for monozukuri in Japan by providing youth with the opportunity to experience monozukuri and feel a sense of accomplishment through the hands-on process. Our kits are not only for children, but can also be enjoyed by adults with their younger generations.

Our Products

Semiconductor manufacturing line conveyors and storage equipment

We have engaged in this work for nearly 20 years since our founding. These are the main products that we design.

Other Products

- Automated carriers for nuclear power plants

- Automated carriers for refrigeration facilities

- Medical testing chip manufacturing equipment

- Ultrasonic cleaning equipment

- Jet shower cleaning machines

- Oxygen cleaning machines

- Carbon cooling equipment

Service Procedure

Order

First, we receive an inquiry from a client that includes their desired specifications.

Discuss specifications

Our representatives meet with the client directly to learn what they want.

Concept design

We solidify concepts such as rough specifications and structures based on the client’s desires, and create the design.

Finalize specifications

We confirm the concept design with the client, and fine-tune it to finalize specifications.

Detailed design

Once the specifications are finalized, we create a detailed design that includes detailed structures and dimensions.

Delivery of drawings

We deliver the drawings, and our work is complete.